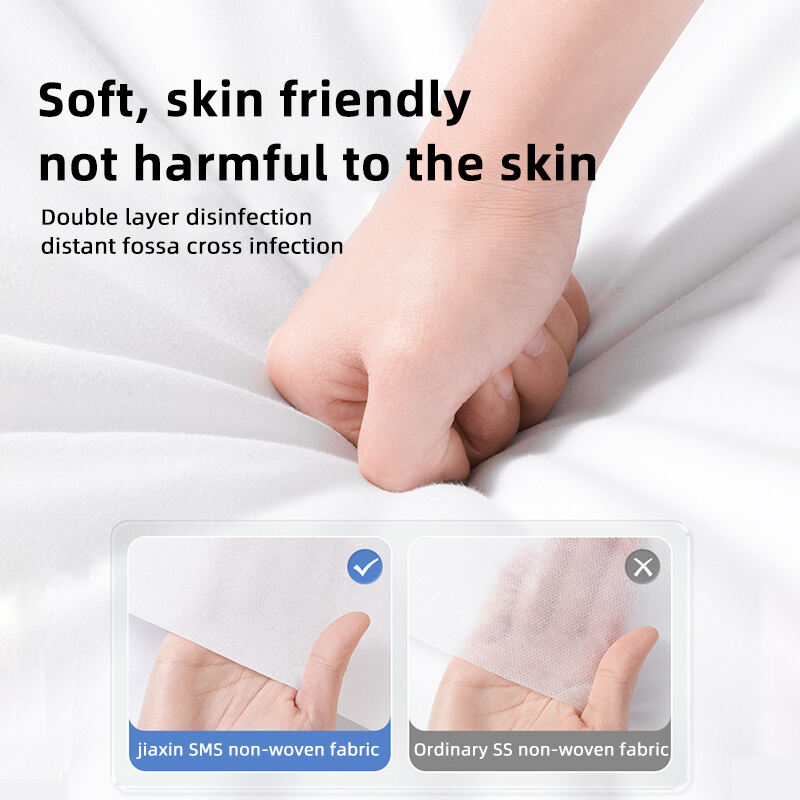

Advanced Sterility Maintenance

One of the unique selling points of medical sterile packaging is its ability to maintain sterility throughout the product's lifecycle. This is achieved through the use of high-barrier materials that block the entry of bacteria and other contaminants. The importance of this feature cannot be overstated, as it directly impacts patient safety and the efficacy of medical treatments. By ensuring that medical devices and instruments remain sterile, this packaging helps healthcare providers to minimize the risk of infections, which can lead to serious complications and increased healthcare costs.