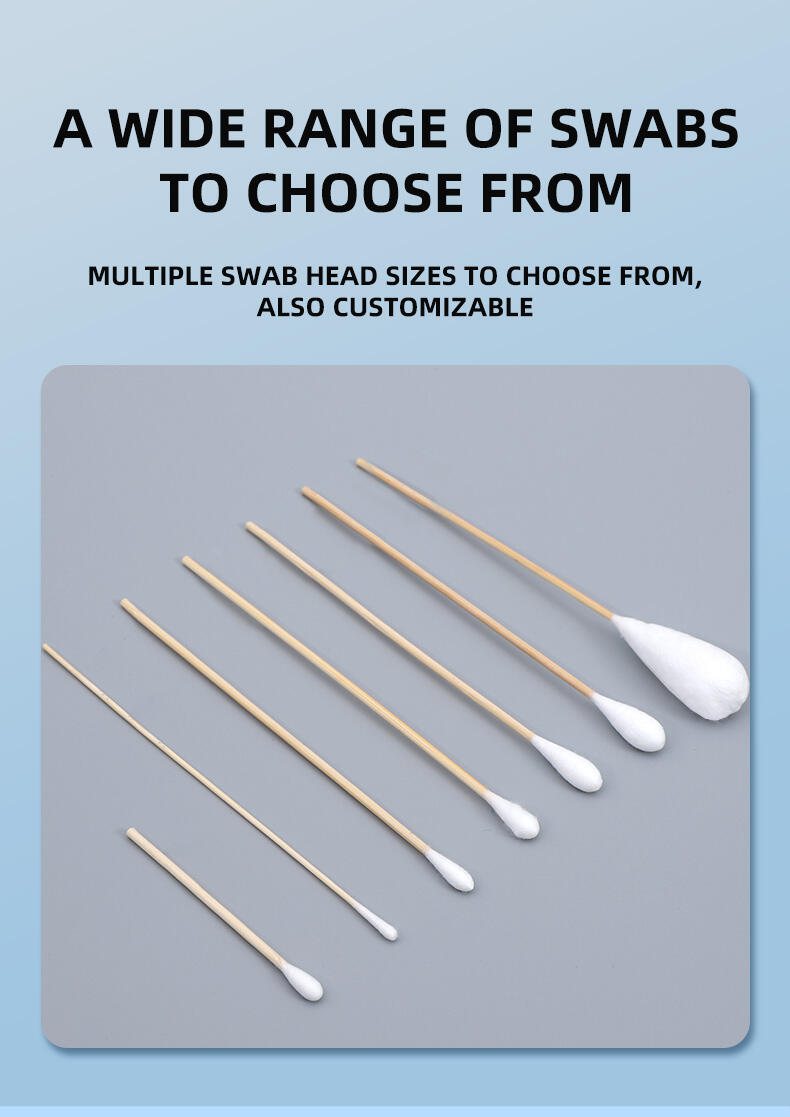

Real-Time Quality Assurance

The sensor for cotton sliver provides real-time quality assurance by continuously measuring key parameters such as thickness, density, and evenness. This feature ensures that any deviations from the set quality standards are immediately identified and corrected, resulting in a consistently high-quality product. For manufacturers, this means reduced waste, lower production costs, and a competitive edge in the market.