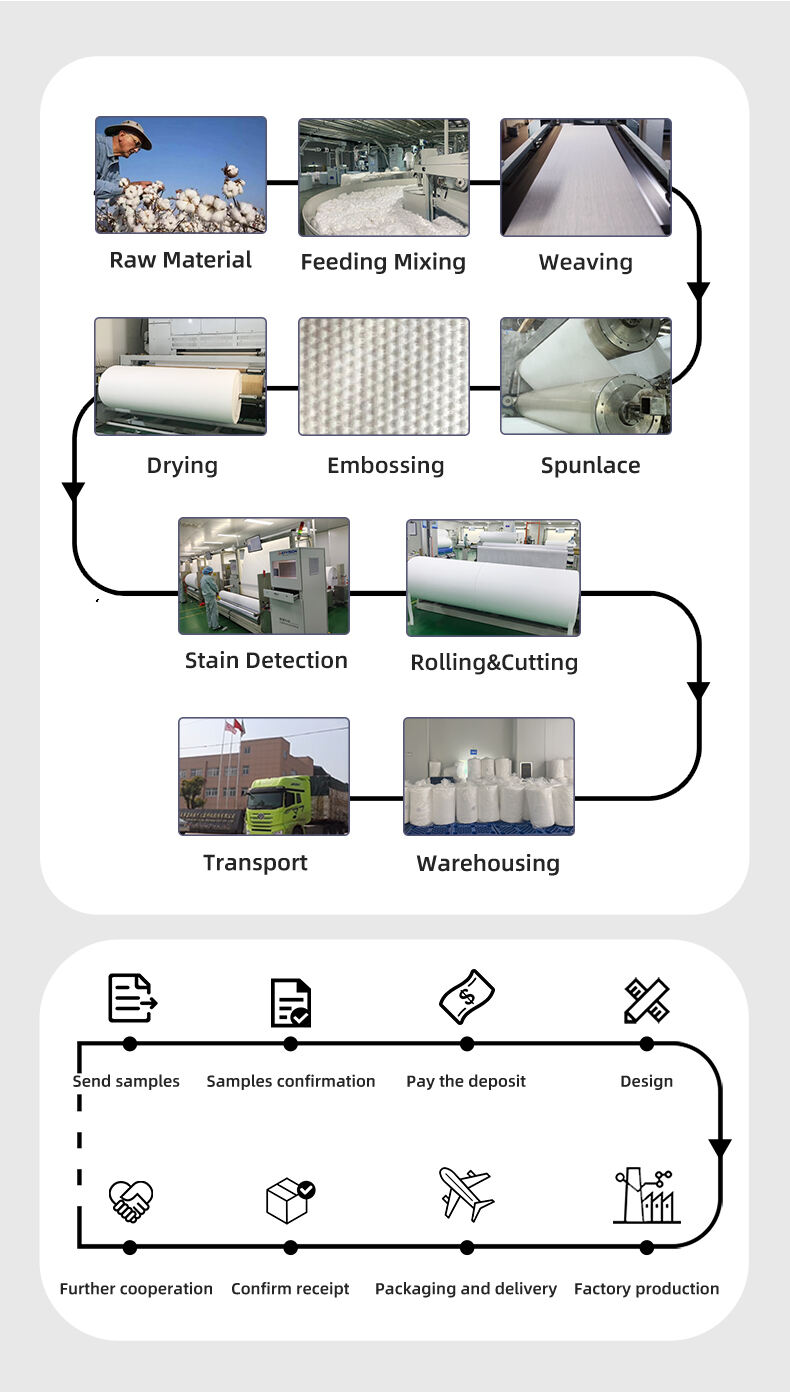

Precision Dosing for Consistency

One of the alcohol pad machine's unique selling points is its precision dosing system. This feature ensures that each alcohol pad contains the exact amount of liquid required, leading to consistent quality across all products. For customers, this consistency means reliable performance in cleaning and disinfecting tasks. The precision dosing system is a cornerstone of the machine's functionality, contributing to customer satisfaction and the reputation of the products it helps create.